Page 134 - Demo

P. 134

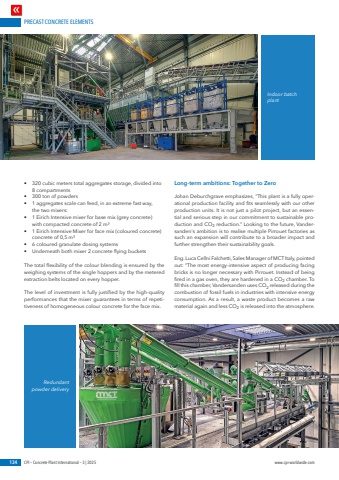

PRECAST CONCRETE ELEMENTS134 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.com%u2022 320 cubic meters total aggregates storage, divided into 8 compartments %u2022 300 ton of powders%u2022 1 aggregates scale can feed, in an extreme fast way, the two mixers: %u2022 1 Eirich Intensive mixer for base mix (grey concrete) with compacted concrete of 2 m%u00b3 %u2022 1 Eirich Intensive Mixer for face mix (coloured concrete) concrete of 0,5 m%u00b3 %u2022 6 coloured granulate dosing systems %u2022 Underneath both mixer 2 concrete flying buckets The total flexibility of the colour blending is ensured by the weighing systems of the single hoppers and by the metered extraction belts located on every hopper. The level of investment is fully justified by the high-quality performances that the mixer guarantees in terms of repetitiveness of homogeneous colour concrete for the face mix. Long-term ambitions: Together to ZeroJohan Deburchgrave emphasizes, %u201cThis plant is a fully operational production facility and fits seamlessly with our other production units. It is not just a pilot project, but an essential and serious step in our commitment to sustainable production and CO2 reduction.%u201d Looking to the future, Vandersanden's ambition is to realise multiple Pirrouet factories as such an expansion will contribute to a broader impact and further strengthen their sustainability goals.Eng. Luca Cellni Falchetti, Sales Manager of MCT Italy, pointed out: %u201cThe most energy-intensive aspect of producing facing bricks is no longer necessary with Pirrouet. Instead of being fired in a gas oven, they are hardened in a CO2 chamber. To fill this chamber, Vandersanden uses CO2 released during the combustion of fossil fuels in industries with intensive energy consumption. As a result, a waste product becomes a raw material again and less CO2 is released into the atmosphere.Indoor batch plantRedundant powder delivery