Page 110 - Demo

P. 110

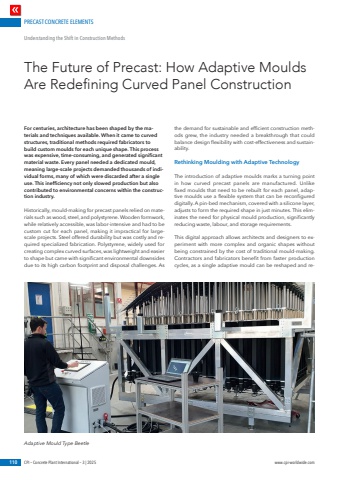

PRECAST CONCRETE ELEMENTS110 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comFor centuries, architecture has been shaped by the materials and techniques available. When it came to curved structures, traditional methods required fabricators to build custom moulds for each unique shape. This process was expensive, time-consuming, and generated significant material waste. Every panel needed a dedicated mould, meaning large-scale projects demanded thousands of individual forms, many of which were discarded after a single use. This inefficiency not only slowed production but also contributed to environmental concerns within the construction industry.Historically, mould-making for precast panels relied on materials such as wood, steel, and polystyrene. Wooden formwork, while relatively accessible, was labor-intensive and had to be custom cut for each panel, making it impractical for largescale projects. Steel offered durability but was costly and required specialized fabrication. Polystyrene, widely used for creating complex curved surfaces, was lightweight and easier to shape but came with significant environmental downsides due to its high carbon footprint and disposal challenges. As the demand for sustainable and efficient construction methods grew, the industry needed a breakthrough that could balance design flexibility with cost-effectiveness and sustainability.Rethinking Moulding with Adaptive TechnologyThe introduction of adaptive moulds marks a turning point in how curved precast panels are manufactured. Unlike fixed moulds that need to be rebuilt for each panel, adaptive moulds use a flexible system that can be reconfigured digitally. A pin-bed mechanism, covered with a silicone layer, adjusts to form the required shape in just minutes. This eliminates the need for physical mould production, significantly reducing waste, labour, and storage requirements.This digital approach allows architects and designers to experiment with more complex and organic shapes without being constrained by the cost of traditional mould-making. Contractors and fabricators benefit from faster production cycles, as a single adaptive mould can be reshaped and reThe Future of Precast: How Adaptive Moulds Are Redefining Curved Panel ConstructionUnderstanding the Shift in Construction MethodsAdaptive Mould Type Beetle