Page 13 - Demo

P. 13

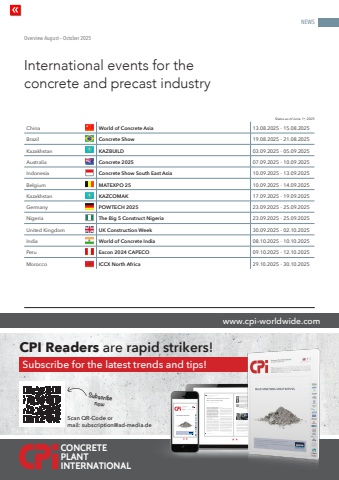

NEWSwww.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 4 | 2025 13China World of Concrete Asia 13.08.2025 - 15.08.2025Brazil Concrete Show 19.08.2025 - 21.08.2025Kazakhstan KAZBUILD 03.09.2025 - 05.09.2025Australia Concrete 2025 07.09.2025 - 10.09.2025Indonesia Concrete Show South East Asia 10.09.2025 - 13.09.2025Belgium MATEXPO 25 10.09.2025 - 14.09.2025Kazakhstan KAZCOMAK 17.09.2025 - 19.09.2025Germany POWTECH 2025 23.09.2025 - 25.09.2025Nigeria The Big 5 Construct Nigeria 23.09.2025 - 25.09.2025United Kingdom UK Construction Week 30.09.2025 - 02.10.2025India World of Concrete India 08.10.2025 - 10.10.2025Peru Excon 2024 CAPECO 09.10.2025 - 12.10.2025Morocco ICCX North Africa 29.10.2025 - 30.10.2025International events for the concrete and precast industryOverview August %u2013 October 2025Status as of June 1st, 2025www.cpi-worldwide.com66 CPI %u2013 Concrete Plant International %u2013 5 | 2024 www.cpi-worldwide.com www.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 5 | 2024Fig. 1: 3D printing of permanent formwork with SHCC for the construction of 4.2 m columns [4].3D concrete printing offers high geometric freedom, allowing the creation of structures with curved shapes, as well as the creation of topologically optimized thin-walled structures. However, the use of conventional steel rebars, which are not flexible and require a relatively thick concrete cover, makes it nearly impossible to utilize these advantages of the new technology. Additionally, the rigidity of steel rods significantly complicates the process of their automated integration. For these reasons, fiber reinforcement, which is devoid of these disadvantages, is a more suitable alternative. Furthermore, non-metallic fibers are resistant to corrosion, and in the case of continuous fibers, a specially developed mineral impregnation allows them to remain flexible for several hours, making it much easier to automate the reinforcement integration during 3D concrete printing. This publication presents various approaches to the integration of short and %u0441ontinuous fibers as developed at TU Dresden and discusses the suitable applications for these types of reinforcement. 3D concrete printing by layer-by-layer extrusion (hereinafter referred to as 3DCP) has become widespread in recent years, but the issue of reinforcement integration remains not fully resolved [1]. Conventional steel rebars, although often used in 3DCP projects due to their availability and extensive application experience, are not always suitable for combining with this technology. They are not flexible enough, thus limiting the geometrical freedom that 3DCP offers. In addition, their low flexibility makes it difficult to automate their installation, so they are usually placed manually, reducing the overall level of automation of the technology. In addition, steel reinforcement is prone to corrosion, so it requires a fairly thick concrete cover, not allowing for thin-walled structures. Highly flexible and non-corrosive fibers do not have these disadvantages and can therefore be a worthy alternative. They are lighter than steel, have higher tensile strength, and their integration during 3DCP can be fully automated. For reinforcement, both short and continuous fibers can be used. The following sections describe the various existing methods of integrating these types of reinforcement as well as their possible applications.Short fibersShort fibers made from a variety of materials can be used for 3D printing, including polyethylene, polyvinyl alcohol, polypropylene, carbon, glass, and basalt. For their integration, no extra equipment is usually required as they can be premixed into the dry mortar or added during concrete mixing. The addition of short fibers at these stages, however, can result in reduced pumpability and extrudability of the material, which may eventually lead to blockages. This problem can be overcome by adjusting the rheology of the concrete matrix and printing procedure or by using more sophisticated printheads, in which fibers are mixed into the concrete just prior to extrusion [2].The addition of short fibers has a number of positive effects. Fibers can significantly improve the mechanical performance of the printed material and prevent the opening of cracks caused by shrinkage [1]. The latter is especially important for 3DCP as printed structures are particularly susceptible to shrinkage deformations. Their surface is not protected from evaporation, and typically 3D printing materials have a high binder content and do not contain coarse aggregate.3DCP provides an opportunity for rational material utilization by producing thin-walled structures that can be designed based on topological optimization. However, since concrete is a brittle material, thin printed structures are susceptible to damage in the event of high localized or dynamic loads. The problem of concrete brittleness in 3DCP can be addressed by using Strain Hardening Cementitious Composites (SHCC) [3]. This type of material, reinforced with short fibers added typically 1-2% by volume, exhibits high ductility and energy absorption. In addition, it possesses high durability since the fibers prevent the opening of cracks and protect the concrete from penetration of water and aggressive agents.SHCC is well suited for 3D printing of permanent formwork, which was demonstrated by Shimizu Corporation in the construction of 4.2 m columns with unique geometry [4], see Fig. 1. The material used for printing was based on the developReinforcement with short and continuous fibers in 3D concrete printing Reinforcement in 3D concrete printingn Egor Ivaniuk, Tobias Neef, Viktor Mechtcherine, TU Dresden, Germanyments carried out at TU Dresden [5]. During construction, the stay-in-place formwork made of SHCC proved to be strong enough to withstand the hydrostatic pressure of the fresh concrete poured inside. Once the columns are created, the outer layer of SHCC acts as a protective barrier, increasing the durability and resistance of the columns to possible impacts.Another application of SHCC is the printing of prefabricated modules. During transportation and assembly of modules local dynamic loads are almost inevitable, and this material type allows to protect them from cracking and spalling. An example of such an application is the %u201cAdaptive Concrete Diamond Construction (ACDC)%u201d project being developed at TU Dresden. In this project, SHCC is used to print the contours of modules for concrete shell assembly [6], see Fig. 2. n Egor Ivaniuk is a Doctoral Researcher at TU Dresden, where he received his M.S. in the program Advanced Computational and Civil Engineering Structural Studies (ACCESS). His research interests include 3D concrete printing, strain-hardening cementitious composites, and textile reinforcement.egor.ivaniuk@tu-dresden.den Tobias Neef is a Doctoral Researcher at TU Dresden, where he participates in the CRC-TRR 280 project. His research interests include 3D concrete printing with a continuous mineral-impregnated fiber reinforcement. Another topic is the fabrication of complex shell elements through robotically depositing concrete layers on multi-curved carbon reinforcement structures.tobias.neef@tu-dresden.den VViktor Mechtcherine has served as a Professor and Director of the Institute of Construction Materials, Faculty of Civil Engineering at TU Dresden, since 2006. He is Editor of the Journals %u201cCement and Concrete Composites%u201d and %u201cMaterials and Structures%u201d, Member of the ACATECH German National Academy of Science and Engineering and the Science Academy of Saxony, RILEM Fellow and awardee of Wason Medal for Materials Research by American Concrete Institute (ACI).viktor.mechtcherine@tu-dresden.de2206_dudik.indd 2 06.05.22 14:571 www.cpi-worldwide.com2025Concrete Plant InternationalWorldwide English EditionNEWS Digital monitoring system to make concreting more reliable, safer and more economical CONCRETE TECHNOLOGY Characterization of raw recycled aggregates for use in concrete products CONCRETE PRODUCTS Ecomix Ltd. from Bulgaria with ground-breaking investment for the future PRECAST CONCRETE ELEMENTS New project in Greece FAIRS & EVENTS bauma 2025 MIXED AND COMPACTED Concrete spheres as electricity storageFor some, it%u2019s just a heap of grey material. But for our customers, it%u2019s the source of limitless possibilities %u2013 in architecture, road construction and landscaping. Be it production boards or Wetcast moulds: We support you in bringing your design ideas to life. Let%u2019s turn possibilities into reality!BUILD SOMETHING GREAT WITH US. Scan QR-Code or mail: subscription@ad-media.deSubscribe nowCONCRETE PLANTINTERNATIONALTRADE JOURNALS FOR THE CONCRETE INDUSTRYCPI Readers are rapid strikers!Subscribe for the latest trends and tips!