Page 65 - Demo

P. 65

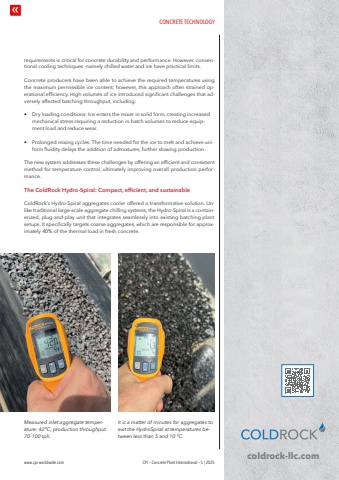

CONCRETE TECHNOLOGYwww.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 5 | 2025requirements is critical for concrete durability and performance. However, conventional cooling techniques -namely chilled water and ice have practical limits.Concrete producers have been able to achieve the required temperatures using the maximum permissible ice content; however, this approach often strained operational efficiency. High volumes of ice introduced significant challenges that adversely affected batching throughput, including:%u2022 Dry loading conditions: Ice enters the mixer in solid form, creating increased mechanical stress requiring a reduction in batch volumes to reduce equipment load and reduce wear.%u2022 Prolonged mixing cycles: The time needed for the ice to melt and achieve uniform fluidity delays the addition of admixtures, further slowing production.The new system addresses these challenges by offering an efficient and consistent method for temperature control, ultimately improving overall production performance.The ColdRock Hydro-Spiral: Compact, efficient, and sustainableColdRock%u2019s Hydro-Spiral aggregates cooler offered a transformative solution. Unlike traditional large-scale aggregate chilling systems, the Hydro-Spiral is a containerized, plug-and-play unit that integrates seamlessly into existing batching plant setups. It specifically targets coarse aggregates, which are responsible for approximately 40% of the thermal load in fresh concrete.Measured inlet aggregate temperature: 42%u00b0C, production throughput 70-100 tph.It is a matter of minutes for aggregates to exit the HydroSpiral at temperatures between less than 5 and 10 %u00b0C.coldrock-llc.com