Page 162 - Demo

P. 162

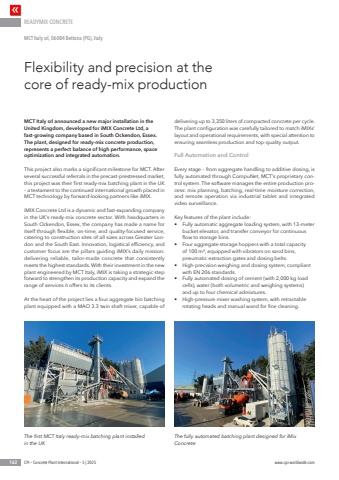

READYMIX CONCRETE162 CPI %u2013 Concrete Plant International %u2013 5 | 2025 www.cpi-worldwide.comMCT Italy srl announced a new major installation in the United Kingdom, developed for iMIX Concrete Ltd, a fast-growing company based in South Ockendon, Essex. The plant, designed for ready-mix concrete production, represents a perfect balance of high performance, space optimization and integrated automation.This project also marks a significant milestone for MCT. After several successful referrals in the precast-prestressed market, this project was their first ready-mix batching plant in the UK %u2013 a testament to the continued international growth placed in MCT technology by forward-looking partners like iMIX.iMIX Concrete Ltd is a dynamic and fast-expanding company in the UK%u2019s ready-mix concrete sector. With headquarters in South Ockendon, Essex, the company has made a name for itself through flexible, on-time, and quality-focused service, catering to construction sites of all sizes across Greater London and the South East. Innovation, logistical efficiency, and customer focus are the pillars guiding iMIX%u2019s daily mission: delivering reliable, tailor-made concrete that consistently meets the highest standards. With their investment in the new plant engineered by MCT Italy, iMIX is taking a strategic step forward to strengthen its production capacity and expand the range of services it offers to its clients.At the heart of the project lies a four aggregate bin batching plant equipped with a MAO 3.3 twin shaft mixer, capable of delivering up to 3,350 liters of compacted concrete per cycle. The plant configuration was carefully tailored to match iMIXs%u2019 layout and operational requirements, with special attention to ensuring seamless production and top-quality output.Full Automation and ControlEvery stage %u2013 from aggregate handling to additive dosing, is fully automated through CompuNet, MCT%u2019s proprietary control system. The software manages the entire production process: mix planning, batching, real-time moisture correction, and remote operation via industrial tablet and integrated video surveillance.Key features of the plant include:%u2022 Fully automatic aggregate loading system, with 13-meter bucket elevator, and transfer conveyor for continuous flow to storage bins.%u2022 Four aggregate storage hoppers with a total capacity of 100 m%u00b3, equipped with vibrators on sand bins, pneumatic extraction gates and dosing belts.%u2022 High-precision weighing and dosing system, compliant with EN 206 standards.%u2022 Fully automated dosing of cement (with 2,000 kg load cells), water (both volumetric and weighing systems) and up to four chemical admixtures.%u2022 High-pressure mixer washing system, with retractable rotating heads and manual wand for fine cleaning.Flexibility and precision at the core of ready-mix productionMCT Italy srl, 06084 Bettona (PG), Italy The first MCT Italy ready-mix batching plant installed in the UKThe fully automated batching plant designed for iMix Concrete