Page 46 - Demo

P. 46

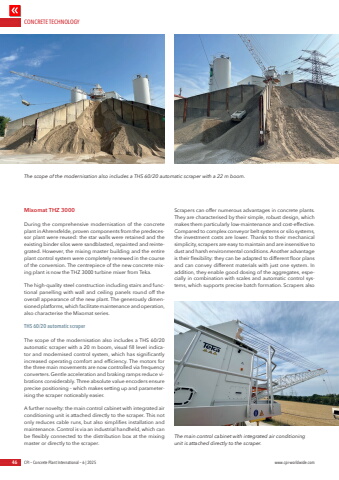

CONCRETE TECHNOLOGY46 CPI %u2013 Concrete Plant International %u2013 6 | 2025 www.cpi-worldwide.comMixomat THZ 3000During the comprehensive modernisation of the concrete plant in Ahrensfelde, proven components from the predecessor plant were reused: the star walls were retained and the existing binder silos were sandblasted, repainted and reintegrated. However, the mixing master building and the entire plant control system were completely renewed in the course of the conversion. The centrepiece of the new concrete mixing plant is now the THZ 3000 turbine mixer from Teka.The high-quality steel construction including stairs and functional panelling with wall and ceiling panels round off the overall appearance of the new plant. The generously dimensioned platforms, which facilitate maintenance and operation, also characterise the Mixomat series.THS 60/20 automatic scraperThe scope of the modernisation also includes a THS 60/20 automatic scraper with a 20 m boom, visual fill level indicator and modernised control system, which has significantly increased operating comfort and efficiency. The motors for the three main movements are now controlled via frequency converters. Gentle acceleration and braking ramps reduce vibrations considerably. Three absolute value encoders ensure precise positioning %u2013 which makes setting up and parameterising the scraper noticeably easier.A further novelty: the main control cabinet with integrated air conditioning unit is attached directly to the scraper. This not only reduces cable runs, but also simplifies installation and maintenance. Control is via an industrial handheld, which can be flexibly connected to the distribution box at the mixing master or directly to the scraper.Scrapers can offer numerous advantages in concrete plants. They are characterised by their simple, robust design, which makes them particularly low-maintenance and cost-effective. Compared to complex conveyor belt systems or silo systems, the investment costs are lower. Thanks to their mechanical simplicity, scrapers are easy to maintain and are insensitive to dust and harsh environmental conditions. Another advantage is their flexibility: they can be adapted to different floor plans and can convey different materials with just one system. In addition, they enable good dosing of the aggregates, especially in combination with scales and automatic control systems, which supports precise batch formation. Scrapers also The scope of the modernisation also includes a THS 60/20 automatic scraper with a 22 m boom.The main control cabinet with integrated air conditioning unit is attached directly to the scraper.