Page 113 - Demo

P. 113

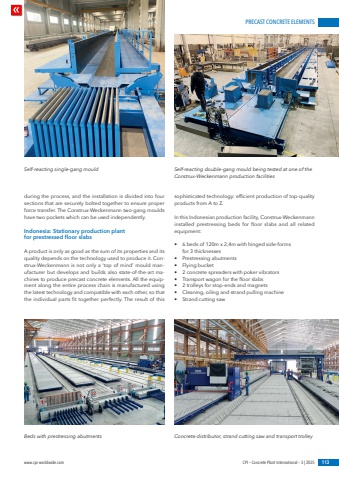

PRECAST CONCRETE ELEMENTSwww.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 3 | 2025 113during the process, and the installation is divided into four sections that are securely bolted together to ensure proper force transfer. The Construx-Weckenmann two-gang moulds have two pockets which can be used independently. Indonesia: Stationary production plant for prestressed floor slabsA product is only as good as the sum of its properties and its quality depends on the technology used to produce it. Construx-Weckenmann is not only a %u2018top of mind%u2019 mould manufacturer but develops and builds also state-of-the-art machines to produce precast concrete elements. All the equipment along the entire process chain is manufactured using the latest technology and compatible with each other, so that the individual parts fit together perfectly. The result of this sophisticated technology: efficient production of top-quality products from A to Z.In this Indonesian production facility, Construx-Weckenmann installed prestressing beds for floor slabs and all related equipment:%u2022 6 beds of 120m x 2,4m with hinged side-forms for 3 thicknesses%u2022 Prestressing abutments%u2022 Flying bucket%u2022 2 concrete spreaders with poker vibrators%u2022 Transport wagon for the floor slabs%u2022 2 trolleys for stop-ends and magnets%u2022 Cleaning, oiling and strand pulling machine%u2022 Strand cutting sawBeds with prestressing abutmentsSelf-reacting single-gang mouldConcrete distributor, strand cutting saw and transport trolleySelf-reacting double-gang mould being tested at one of the Construx-Weckenmann production facilities