Page 132 - Demo

P. 132

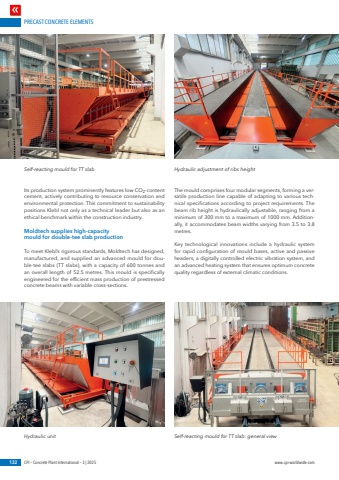

PRECAST CONCRETE ELEMENTS132 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comIts production system prominently features low CO2-content cement, actively contributing to resource conservation and environmental protection. This commitment to sustainability positions Klebl not only as a technical leader but also as an ethical benchmark within the construction industry.Moldtech supplies high-capacity mould for double-tee slab productionTo meet Klebl%u2019s rigorous standards, Moldtech has designed, manufactured, and supplied an advanced mould for double-tee slabs (TT slabs), with a capacity of 600 tonnes and an overall length of 52.5 metres. This mould is specifically engineered for the efficient mass production of prestressed concrete beams with variable cross-sections.The mould comprises four modular segments, forming a versatile production line capable of adapting to various technical specifications according to project requirements. The beam rib height is hydraulically adjustable, ranging from a minimum of 300 mm to a maximum of 1000 mm. Additionally, it accommodates beam widths varying from 3.5 to 3.8 metres.Key technological innovations include a hydraulic system for rapid configuration of mould bases, active and passive headers, a digitally controlled electric vibration system, and an advanced heating system that ensures optimum concrete quality regardless of external climatic conditions.Self-reacting mould for TT slabHydraulic unitHydraulic adjustment of ribs heightSelf-reacting mould for TT slab: general view