Page 42 - Demo

P. 42

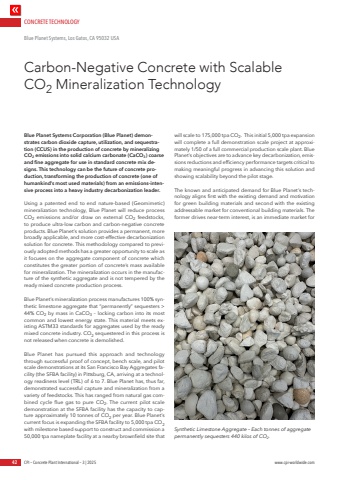

CONCRETE TECHNOLOGY42 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comBlue Planet Systems Corporation (Blue Planet) demonstrates carbon dioxide capture, utilization, and sequestration (CCUS) in the production of concrete by mineralizing CO2 emissions into solid calcium carbonate (CaCO3) coarse and fine aggregate for use in standard concrete mix designs. This technology can be the future of concrete production, transforming the production of concrete (one of humankind%u2019s most used materials) from an emissions-intensive process into a heavy industry decarbonization leader. Using a patented end to end nature-based (Geomimetic) mineralization technology, Blue Planet will reduce process CO2 emissions and/or draw on external CO2 feedstocks, to produce ultra-low carbon and carbon-negative concrete products. Blue Planet%u2019s solution provides a permanent, more broadly applicable, and more cost-effective decarbonization solution for concrete. This methodology compared to previously adopted methods has a greater opportunity to scale as it focuses on the aggregate component of concrete which constitutes the greater portion of concrete%u2019s mass available for mineralization. The mineralization occurs in the manufacture of the synthetic aggregate and is not tempered by the ready mixed concrete production process.Blue Planet%u2019s mineralization process manufactures 100% synthetic limestone aggregate that %u201cpermanently%u201d sequesters > 44% CO2 by mass in CaCO3 %u2013 locking carbon into its most common and lowest energy state. This material meets existing ASTM33 standards for aggregates used by the ready mixed concrete industry. CO2 sequestered in this process is not released when concrete is demolished.Blue Planet has pursued this approach and technology through successful proof of concept, bench scale, and pilot scale demonstrations at its San Francisco Bay Aggregates facility (the SFBA facility) in Pittsburg, CA, arriving at a technology readiness level (TRL) of 6 to 7. Blue Planet has, thus far, demonstrated successful capture and mineralization from a variety of feedstocks. This has ranged from natural gas combined cycle flue gas to pure CO2. The current pilot scale demonstration at the SFBA facility has the capacity to capture approximately 10 tonnes of CO2 per year. Blue Planet%u2019s current focus is expanding the SFBA facility to 5,000 tpa CO2with milestone based support to construct and commission a 50,000 tpa nameplate facility at a nearby brownfield site that will scale to 175,000 tpa CO2. This initial 5,000 tpa expansion will complete a full demonstration scale project at approximately 1/50 of a full commercial production scale plant. Blue Planet%u2019s objectives are to advance key decarbonization, emissions reductions and efficiency performance targets critical to making meaningful progress in advancing this solution and showing scalability beyond the pilot stage.The known and anticipated demand for Blue Planet%u2019s technology aligns first with the existing demand and motivation for green building materials and second with the existing addressable market for conventional building materials. The former drives near-term interest, is an immediate market for Carbon-Negative Concrete with Scalable CO2 Mineralization TechnologyBlue Planet Systems, Los Gatos, CA 95032 USASynthetic Limestone Aggregate %u2013 Each tonnes of aggregate permanently sequesters 440 kilos of CO2.