Page 38 - Demo

P. 38

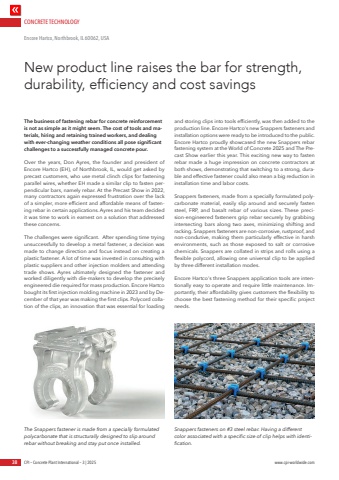

CONCRETE TECHNOLOGY38 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comThe business of fastening rebar for concrete reinforcement is not as simple as it might seem. The cost of tools and materials, hiring and retaining trained workers, and dealing with ever-changing weather conditions all pose significant challenges to a successfully managed concrete pour. Over the years, Don Ayres, the founder and president of Encore Hartco (EH), of Northbrook, IL, would get asked by precast customers, who use metal clinch clips for fastening parallel wires, whether EH made a similar clip to fasten perpendicular bars, namely rebar. At the Precast Show in 2022, many contractors again expressed frustration over the lack of a simpler, more efficient and affordable means of fastening rebar in certain applications. Ayres and his team decided it was time to work in earnest on a solution that addressed these concerns.The challenges were significant. After spending time trying unsuccessfully to develop a metal fastener, a decision was made to change direction and focus instead on creating a plastic fastener. A lot of time was invested in consulting with plastic suppliers and other injection molders and attending trade shows. Ayres ultimately designed the fastener and worked diligently with die-makers to develop the precisely engineered die required for mass production. Encore Hartco bought its first injection molding machine in 2023 and by December of that year was making the first clips. Polycord collation of the clips, an innovation that was essential for loading and storing clips into tools efficiently, was then added to the production line. Encore Hartco's new Snappers fasteners and installation options were ready to be introduced to the public.Encore Hartco proudly showcased the new Snappers rebar fastening system at the World of Concrete 2025 and The Precast Show earlier this year. This exciting new way to fasten rebar made a huge impression on concrete contractors at both shows, demonstrating that switching to a strong, durable and effective fastener could also mean a big reduction in installation time and labor costs. Snappers fasteners, made from a specially formulated polycarbonate material, easily slip around and securely fasten steel, FRP, and basalt rebar of various sizes. These precision-engineered fasteners grip rebar securely by grabbing intersecting bars along two axes, minimizing shifting and racking. Snappers fasteners are non-corrosive, rustproof, and non-condutive, making them particularly effective in harsh environments, such as those exposed to salt or corrosive chemicals. Snappers are collated in strips and rolls using a flexible polycord, allowing one universal clip to be applied by three different installation modes. Encore Hartco's three Snappers application tools are intentionally easy to operate and require little maintenance. Importantly, their affordability gives customers the flexibility to choose the best fastening method for their specific project needs.New product line raises the bar for strength, durability, efficiency and cost savingsEncore Hartco, Northbrook, IL 60062, USAThe Snappers fastener is made from a specially formulated polycarbonate that is structurally designed to slip around rebar without breaking and stay put once installed.Snappers fasteners on #3 steel rebar. Having a different color associated with a specific size of clip helps with identification.