Page 52 - Demo

P. 52

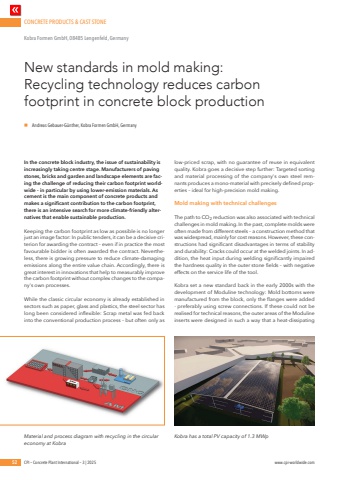

CONCRETE PRODUCTS & CAST STONE52 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comIn the concrete block industry, the issue of sustainability is increasingly taking centre stage. Manufacturers of paving stones, bricks and garden and landscape elements are facing the challenge of reducing their carbon footprint worldwide - in particular by using lower-emission materials. As cement is the main component of concrete products and makes a significant contribution to the carbon footprint, there is an intensive search for more climate-friendly alternatives that enable sustainable production.Keeping the carbon footprint as low as possible is no longer just an image factor: In public tenders, it can be a decisive criterion for awarding the contract %u2013 even if in practice the most favourable bidder is often awarded the contract. Nevertheless, there is growing pressure to reduce climate-damaging emissions along the entire value chain. Accordingly, there is great interest in innovations that help to measurably improve the carbon footprint without complex changes to the company's own processes.While the classic circular economy is already established in sectors such as paper, glass and plastics, the steel sector has long been considered inflexible: Scrap metal was fed back into the conventional production process %u2013 but often only as low-priced scrap, with no guarantee of reuse in equivalent quality. Kobra goes a decisive step further: Targeted sorting and material processing of the company's own steel remnants produces a mono-material with precisely defined properties %u2013 ideal for high-precision mold making.Mold making with technical challengesThe path to CO2 reduction was also associated with technical challenges in mold making. In the past, complete molds were often made from different steels %u2013 a construction method that was widespread, mainly for cost reasons. However, these constructions had significant disadvantages in terms of stability and durability: Cracks could occur at the welded joints. In addition, the heat input during welding significantly impaired the hardness quality in the outer stone fields %u2013 with negative effects on the service life of the tool.Kobra set a new standard back in the early 2000s with the development of Moduline technology: Mold bottoms were manufactured from the block, only the flanges were added - preferably using screw connections. If these could not be realised for technical reasons, the outer areas of the Moduline inserts were designed in such a way that a heat-dissipating New standards in mold making: Recycling technology reduces carbon footprint in concrete block productionKobra Formen GmbH, 08485 Lengenfeld, Germanyn Andreas Gebauer-G%u00fcnther, Kobra Formen GmbH, GermanyMaterial and process diagram with recycling in the circular economy at KobraKobra has a total PV capacity of 1.3 MWp