Page 56 - Demo

P. 56

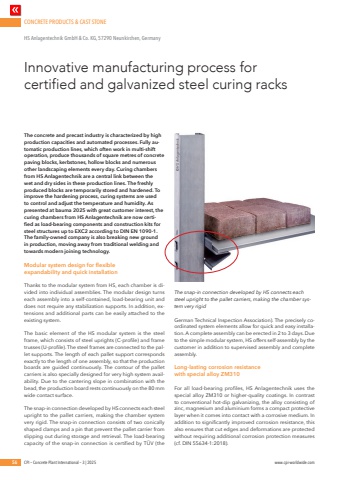

CONCRETE PRODUCTS & CAST STONE56 CPI %u2013 Concrete Plant International %u2013 3 | 2025 www.cpi-worldwide.comThe concrete and precast industry is characterized by high production capacities and automated processes. Fully automatic production lines, which often work in multi-shift operation, produce thousands of square metres of concrete paving blocks, kerbstones, hollow blocks and numerous other landscaping elements every day. Curing chambers from HS Anlagentechnik are a central link between the wet and dry sides in these production lines. The freshly produced blocks are temporarily stored and hardened. To improve the hardening process, curing systems are used to control and adjust the temperature and humidity. As presented at bauma 2025 with great customer interest, the curing chambers from HS Anlagentechnik are now certified as load-bearing components and construction kits for steel structures up to EXC2 according to DIN EN 1090-1. The family-owned company is also breaking new ground in production, moving away from traditional welding and towards modern joining technology. Modular system design for flexible expandability and quick installationThanks to the modular system from HS, each chamber is divided into individual assemblies. The modular design turns each assembly into a self-contained, load-bearing unit and does not require any stabilization supports. In addition, extensions and additional parts can be easily attached to the existing system. The basic element of the HS modular system is the steel frame, which consists of steel uprights (C-profile) and frame trusses (U-profile). The steel frames are connected to the pallet supports. The length of each pallet support corresponds exactly to the length of one assembly, so that the production boards are guided continuously. The contour of the pallet carriers is also specially designed for very high system availability. Due to the cantering slope in combination with the bead, the production board rests continuously on the 80 mm wide contact surface.The snap-in connection developed by HS connects each steel upright to the pallet carriers, making the chamber system very rigid. The snap-in connection consists of two conically shaped clamps and a pin that prevent the pallet carrier from slipping out during storage and retrieval. The load-bearing capacity of the snap-in connection is certified by T%u00dcV (the German Technical Inspection Association). The precisely coordinated system elements allow for quick and easy installation. A complete assembly can be erected in 2 to 3 days. Due to the simple modular system, HS offers self-assembly by the customer in addition to supervised assembly and complete assembly. Long-lasting corrosion resistance with special alloy ZM310For all load-bearing profiles, HS Anlagentechnik uses the special alloy ZM310 or higher-quality coatings. In contrast to conventional hot-dip galvanizing, the alloy consisting of zinc, magnesium and aluminium forms a compact protective layer when it comes into contact with a corrosive medium. In addition to significantly improved corrosion resistance, this also ensures that cut edges and deformations are protected without requiring additional corrosion protection measures (cf. DIN 55634-1:2018). Innovative manufacturing process for certified and galvanized steel curing racks HS Anlagentechnik GmbH & Co. KG, 57290 Neunkirchen, GermanyThe snap-in connection developed by HS connects each steel upright to the pallet carriers, making the chamber system very rigid %u00a9 HS Anlagentechnik