Page 172 - Demo

P. 172

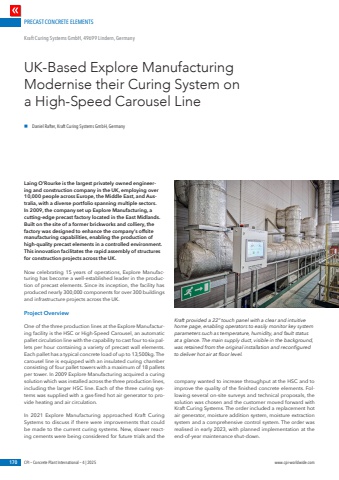

PRECAST CONCRETE ELEMENTS170 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comLaing O%u2019Rourke is the largest privately owned engineering and construction company in the UK, employing over 10,000 people across Europe, the Middle East, and Australia, with a diverse portfolio spanning multiple sectors. In 2009, the company set up Explore Manufacturing, a cutting-edge precast factory located in the East Midlands. Built on the site of a former brickworks and colliery, the factory was designed to enhance the company%u2019s offsite manufacturing capabilities, enabling the production of high-quality precast elements in a controlled environment. This innovation facilitates the rapid assembly of structures for construction projects across the UK.Now celebrating 15 years of operations, Explore Manufacturing has become a well-established leader in the production of precast elements. Since its inception, the facility has produced nearly 300,000 components for over 300 buildings and infrastructure projects across the UK.Project OverviewOne of the three production lines at the Explore Manufacturing facility is the HSC or High-Speed Carousel, an automatic pallet circulation line with the capability to cast four to six pallets per hour containing a variety of precast wall elements. Each pallet has a typical concrete load of up to 13,500kg. The carousel line is equipped with an insulated curing chamber consisting of four pallet towers with a maximum of 18 pallets per tower. In 2009 Explore Manufacturing acquired a curing solution which was installed across the three production lines, including the larger HSC line. Each of the three curing systems was supplied with a gas-fired hot air generator to provide heating and air circulation.In 2021 Explore Manufacturing approached Kraft Curing Systems to discuss if there were improvements that could be made to the current curing systems. New, slower reacting cements were being considered for future trials and the company wanted to increase throughput at the HSC and to improve the quality of the finished concrete elements. Following several on-site surveys and technical proposals, the solution was chosen and the customer moved forward with Kraft Curing Systems. The order included a replacement hot air generator, moisture addition system, moisture extraction system and a comprehensive control system. The order was realised in early 2023, with planned implementation at the end-of-year maintenance shut-down.UK-Based Explore Manufacturing Modernise their Curing System on a High-Speed Carousel LineKraft Curing Systems GmbH, 49699 Lindern, Germanyn Daniel Rafter, Kraft Curing Systems GmbH, GermanyKraft provided a 22%u201d touch panel with a clear and intuitive home page, enabling operators to easily monitor key system parameters such as temperature, humidity, and fault status at a glance. The main supply duct, visible in the background, was retained from the original installation and reconfigured to deliver hot air at floor level.