Page 32 - Demo

P. 32

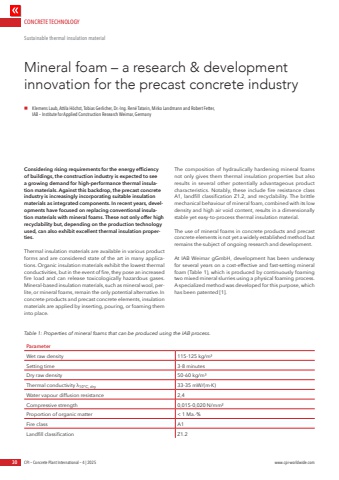

CONCRETE TECHNOLOGY30 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comConsidering rising requirements for the energy efficiency of buildings, the construction industry is expected to see a growing demand for high-performance thermal insulation materials. Against this backdrop, the precast concrete industry is increasingly incorporating suitable insulation materials as integrated components. In recent years, developments have focused on replacing conventional insulation materials with mineral foams. These not only offer high recyclability but, depending on the production technology used, can also exhibit excellent thermal insulation properties.Thermal insulation materials are available in various product forms and are considered state of the art in many applications. Organic insulation materials exhibit the lowest thermal conductivities, but in the event of fire, they pose an increased fire load and can release toxicologically hazardous gases. Mineral-based insulation materials, such as mineral wool, perlite, or mineral foams, remain the only potential alternative. In concrete products and precast concrete elements, insulation materials are applied by inserting, pouring, or foaming them into place.The composition of hydraulically hardening mineral foams not only gives them thermal insulation properties but also results in several other potentially advantageous product characteristics. Notably, these include fire resistance class A1, landfill classification Z1.2, and recyclability. The brittle mechanical behaviour of mineral foam, combined with its low density and high air void content, results in a dimensionally stable yet easy-to-process thermal insulation material.The use of mineral foams in concrete products and precast concrete elements is not yet a widely established method but remains the subject of ongoing research and development.At IAB Weimar gGmbH, development has been underway for several years on a cost-effective and fast-setting mineral foam (Table 1), which is produced by continuously foaming two mixed mineral slurries using a physical foaming process. A specialized method was developed for this purpose, which has been patented [1].Mineral foam %u2013 a research & development innovation for the precast concrete industry Sustainable thermal insulation materialn Klemens Laub, Attila H%u00f6chst, Tobias Gerlicher, Dr.-Ing. Ren%u00e9 Tatarin, Mirko Landmann and Robert Fetter, IAB %u2013 Institute for Applied Construction Research Weimar, GermanyTable 1: Properties of mineral foams that can be produced using the IAB process.ParameterWet raw density 115-125 kg/m%u00b3Setting time 3-8 minutes Dry raw density 50-60 kg/m%u00b3Thermal conductivity %u03bb10%u00b0C, dry 33-35 mW/(m%u00b7K)Water vapour diffusion resistance 2,4Compressive strength 0,015-0,020 N/mm%u00b2Proportion of organic matter < 1 Ma.-%Fire class A1Landfill classification Z1.2