Page 119 - Demo

P. 119

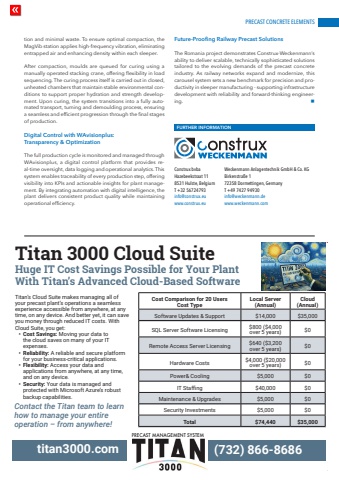

PRECAST CONCRETE ELEMENTStion and minimal waste. To ensure optimal compaction, the MagVib station applies high-frequency vibration, eliminating entrapped air and enhancing density within each sleeper.After compaction, moulds are queued for curing using a manually operated stacking crane, offering flexibility in load sequencing. The curing process itself is carried out in closed, unheated chambers that maintain stable environmental conditions to support proper hydration and strength development. Upon curing, the system transitions into a fully automated transport, turning and demoulding process, ensuring a seamless and efficient progression through the final stages of production.Digital Control with WAvisionplus: Transparency & OptimizationThe full production cycle is monitored and managed through WAvisionplus, a digital control platform that provides real-time oversight, data logging and operational analytics. This system enables traceability of every production step, offering visibility into KPIs and actionable insights for plant management. By integrating automation with digital intelligence, the plant delivers consistent product quality while maintaining operational efficiency.Future-Proofing Railway Precast SolutionsThe Romania project demonstrates Construx-Weckenmann%u2019s ability to deliver scalable, technically sophisticated solutions tailored to the evolving demands of the precast concrete industry. As railway networks expand and modernize, this carousel system sets a new benchmark for precision and productivity in sleeper manufacturing - supporting infrastructure development with reliability and forward-thinking engineering. nFURTHER INFORMATIONConstrux bvba Hazebeekstraat 11 8531 Hulste, Belgium T +32 56724793 info@construx.eu www.construx.eu Weckenmann Anlagentechnik GmbH & Co. KG Birkenstra%u00dfe 1 72358 Dormettingen, Germany T +49 7427 94930 info@weckenmann.de www.weckenmann.comtitan3000.com (732) 866-8686PRECAST MANAGEMENT SYSTEMTitan 3000 Cloud SuiteHuge IT Cost Savings Possible for Your PlantWith Titan%u2019s Advanced Cloud-Based SoftwareCost Comparison for 20 UsersCost TypeLocal Server (Annual) Cloud (Annual)Software Updates & Support $14,000 $35,000SQL Server Software Licensing $800 ($4,000 over 5 years) $0Remote Access Server Licensing $640 ($3,200 over 5 years) $0Hardware Costs $4,000 ($20,000 over 5 years) $0Power& Cooling $5,000 $0IT Staffing $40,000 $0Maintenance & Upgrades $5,000 $0Security Investments $5,000 $0Total $74,440 $35,000Titan%u2019s Cloud Suite makes managing all of your precast plant%u2019s operations a seamless experience accessible from anywhere, at any time, on any device. And better yet, it can save you money through reduced IT costs. With Cloud Suite, you get:%u2022 Cost Savings: Moving your data to the cloud saves on many of your IT expenses. %u2022 Reliability: A reliable and secure platform for your business-critical applications.%u2022 Flexibility: Access your data and applications from anywhere, at any time, and on any device.%u2022 Security: Your data is managed and protected with Microsoft Azure%u2019s robust backup capabilities.Contact the Titan team to learn how to manage your entire operation %u2013 from anywhere!