Page 122 - Demo

P. 122

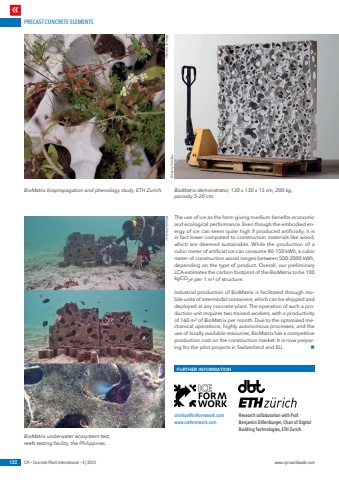

PRECAST CONCRETE ELEMENTS122 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comThe use of ice as the form-giving medium benefits economic and ecological performance. Even though the embodied energy of ice can seem quite high if produced artificially, it is in fact lower compared to construction materials like wood, which are deemed sustainable. While the production of a cubic meter of artificial ice can consume 80-150 kWh, a cubic meter of construction wood ranges between 500-2000 kWh, depending on the type of product. Overall, our preliminary LCA estimates the carbon footprint of the BioMatrix to be 100 kgCO2e per 1 m%u00b3 of structure. Industrial production of BioMatrix is facilitated through mobile units of intermodal containers, which can be shipped and deployed at any concrete plant. The operation of such a production unit requires two trained workers, with a productivity of 160 m%u00b3 of BioMatrix per month. Due to the optimized mechanical operations, highly autonomous processes, and the use of locally available resources, BioMatrix has a competitive production cost on the construction market. It is now preparing for the pilot projects in Switzerland and EU. nFURTHER INFORMATIONResearch collaboration with Prof. Benjamin Dillenburger, Chair of Digital Building Technologies, ETH Zurich.sitnikov@iceformwork.comwww.iceformwork.comBioMatrix biopropagation and phenology study, ETH Zurich. BioMatrix demonstrator, 130 x 130 x 15 cm, 200 kg, porosity 5-20 cm. BioMatrix underwater ecosystem test, reefs testing facility, the Philippines.%u00a9Vasily Sitnikov %u00a9Vasily Sitnikov%u00a9Vasily Sitnikov