Page 55 - Demo

P. 55

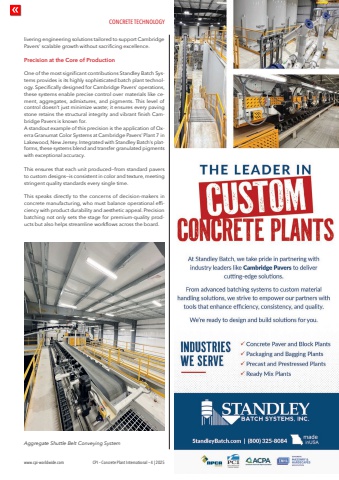

CONCRETE TECHNOLOGYwww.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 4 | 2025livering engineering solutions tailored to support Cambridge Pavers' scalable growth without sacrificing excellence.Precision at the Core of ProductionOne of the most significant contributions Standley Batch Systems provides is its highly sophisticated batch plant technology. Specifically designed for Cambridge Pavers' operations,these systems enable precise control over materials like cement, aggregates, admixtures, and pigments. This level of control doesn%u2019t just minimize waste; it ensures every paving stone retains the structural integrity and vibrant finish Cambridge Pavers is known for.A standout example of this precision is the application of Oxerra Granumat Color Systems at Cambridge Pavers%u2019 Plant 7 in Lakewood, New Jersey. Integrated with Standley Batch%u2019s platforms, these systems blend and transfer granulated pigments with exceptional accuracy.This ensures that each unit produced%u2014from standard pavers to custom designs%u2014is consistent in color and texture, meeting stringent quality standards every single time.This speaks directly to the concerns of decision-makers in concrete manufacturing, who must balance operational efficiency with product durability and aesthetic appeal. Precision batching not only sets the stage for premium-quality products but also helps streamline workflows across the board.Aggregate Shuttle Belt Conveying System