Page 54 - Demo

P. 54

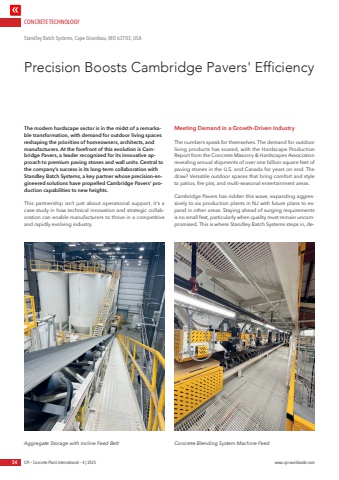

CONCRETE TECHNOLOGY54 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comThe modern hardscape sector is in the midst of a remarkable transformation, with demand for outdoor living spaces reshaping the priorities of homeowners, architects, and manufacturers. At the forefront of this evolution is Cambridge Pavers, a leader recognized for its innovative approach to premium paving stones and wall units. Central to the company%u2019s success is its long-term collaboration with Standley Batch Systems, a key partner whose precision-engineered solutions have propelled Cambridge Pavers%u2019 production capabilities to new heights.This partnership isn%u2019t just about operational support, it%u2019s a case study in how technical innovation and strategic collaboration can enable manufacturers to thrive in a competitive and rapidly evolving industry.Meeting Demand in a Growth-Driven Industry The numbers speak for themselves. The demand for outdoor living products has soared, with the Hardscape Production Report from the Concrete Masonry & Hardscapes Association revealing annual shipments of over one billion square feet of paving stones in the U.S. and Canada for years on end. The draw? Versatile outdoor spaces that bring comfort and style to patios, fire pits, and multi-seasonal entertainment areas.Cambridge Pavers has ridden this wave, expanding aggressively to six production plants in NJ with future plans to expand in other areas. Staying ahead of surging requirements is no small feat, particularly when quality must remain uncompromised. This is where Standley Batch Systems steps in, dePrecision Boosts Cambridge Pavers' EfficiencyStandley Batch Systems, Cape Girardeau, MO 63703, USAAggregate Storage with Incline Feed Belt Concrete Blending System Machine Feed