Page 71 - Demo

P. 71

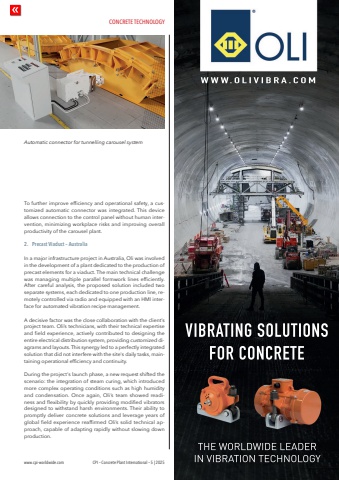

CONCRETE TECHNOLOGYwww.cpi-worldwide.com CPI %u2013 Concrete Plant International %u2013 5 | 2025To further improve efficiency and operational safety, a customized automatic connector was integrated. This device allows connection to the control panel without human intervention, minimizing workplace risks and improving overall productivity of the carousel plant.2. %u0009 Precast Viaduct %u2013 AustraliaIn a major infrastructure project in Australia, Oli was involved in the development of a plant dedicated to the production of precast elements for a viaduct. The main technical challenge was managing multiple parallel formwork lines efficiently. After careful analysis, the proposed solution included two separate systems, each dedicated to one production line, remotely controlled via radio and equipped with an HMI interface for automated vibration recipe management.A decisive factor was the close collaboration with the client%u2019s project team. Oli%u2019s technicians, with their technical expertise and field experience, actively contributed to designing the entire electrical distribution system, providing customized diagrams and layouts. This synergy led to a perfectly integrated solution that did not interfere with the site's daily tasks, maintaining operational efficiency and continuity.During the project's launch phase, a new request shifted the scenario: the integration of steam curing, which introduced more complex operating conditions such as high humidity and condensation. Once again, Oli%u2019s team showed readiness and flexibility by quickly providing modified vibrators designed to withstand harsh environments. Their ability to promptly deliver concrete solutions and leverage years of global field experience reaffirmed Oli%u2019s solid technical approach, capable of adapting rapidly without slowing down production.Automatic connector for tunnelling carousel system