Page 70 - Demo

P. 70

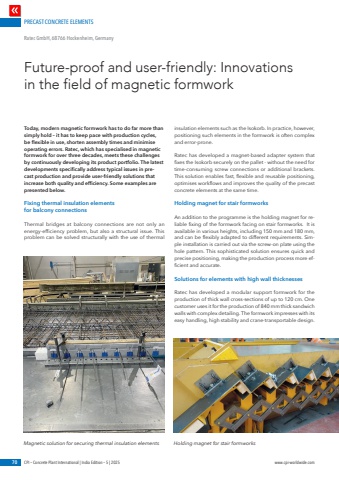

PRECAST CONCRETE ELEMENTS70 CPI %u2013 Concrete Plant International | India Edition %u2013 5 | 2025 www.cpi-worldwide.comToday, modern magnetic formwork has to do far more than simply hold %u2013 it has to keep pace with production cycles, be flexible in use, shorten assembly times and minimise operating errors. Ratec, which has specialised in magnetic formwork for over three decades, meets these challenges by continuously developing its product portfolio. The latest developments specifically address typical issues in precast production and provide user-friendly solutions that increase both quality and efficiency. Some examples are presented below.Fixing thermal insulation elements for balcony connectionsThermal bridges at balcony connections are not only an energy-efficiency problem, but also a structural issue. This problem can be solved structurally with the use of thermal insulation elements such as the Isokorb. In practice, however, positioning such elements in the formwork is often complex and error-prone.Ratec has developed a magnet-based adapter system that fixes the Isokorb securely on the pallet - without the need for time-consuming screw connections or additional brackets. This solution enables fast, flexible and reusable positioning, optimises workflows and improves the quality of the precast concrete elements at the same time.Holding magnet for stair formworksAn addition to the programme is the holding magnet for reliable fixing of the formwork facing on stair formworks. It is available in various heights, including 150 mm and 180 mm, and can be flexibly adapted to different requirements. Simple installation is carried out via the screw-on plate using the hole pattern. This sophisticated solution ensures quick and precise positioning, making the production process more efficient and accurate.Solutions for elements with high wall thicknessesRatec has developed a modular support formwork for the production of thick wall cross-sections of up to 120 cm. One customer uses it for the production of 840 mm thick sandwich walls with complex detailing. The formwork impresses with its easy handling, high stability and crane-transportable design. Future-proof and user-friendly: Innovations in the field of magnetic formworkRatec GmbH, 68766 Hockenheim, GermanyMagnetic solution for securing thermal insulation elements Holding magnet for stair formworks