Page 36 - Demo

P. 36

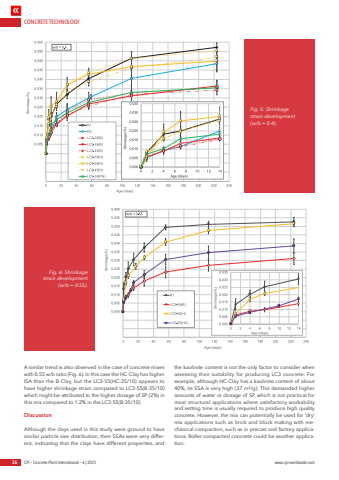

CONCRETE TECHNOLOGY36 CPI %u2013 Concrete Plant International %u2013 6 | 2025 www.cpi-worldwide.comA similar trend is also observed in the case of concrete mixes with 0.55 w/b ratio (Fig. 6). In this case the HC-Clay has higher ISA than the B-Clay, but the LC3-55(HC:35/10) appears to have higher shrinkage strain compared to LC3-55(B:35/10) which might be attributed to the higher dosage of SP (2%) in this mix compared to 1.2% in the LC3-55(B:35/10). DiscussionAlthough the clays used in this study were ground to have similar particle size distribution, their SSAs were very different, indicating that the clays have different properties, and the kaolinite content is not the only factor to consider when assessing their suitability for producing LC3 concrete. For example, although HC-Clay has a kaolinite content of about 40%, its SSA is very high (37 m%u00b2/g). This demanded higher amounts of water or dosage of SP, which is not practical for most structural applications where satisfactory workability and setting time is usually required to produce high quality concrete. However, the mix can potentially be used for %u2018dry%u2019 mix applications such as brick and block making with mechanical compaction, such as in precast and factory applications. Roller-compacted concrete could be another application.Fig. 5: Shrinkage strain development (w/b = 0.4).Fig. 6: Shrinkage strain development (w/b = 0.55).