Page 27 - Demo

P. 27

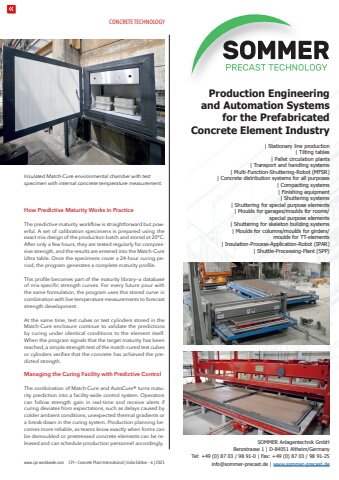

CONCRETE TECHNOLOGYwww.cpi-worldwide.com CPI %u2013 Concrete Plant International | India Edition %u2013 6 | 2025How Predictive Maturity Works in PracticeThe predictive maturity workflow is straightforward but powerful. A set of calibration specimens is prepared using the exact mix design of the production batch and stored at 20%u00b0C. After only a few hours, they are tested regularly for compressive strength, and the results are entered into the Match-Cure Ultra table. Once the specimens cover a 24-hour curing period, the program generates a complete maturity profile.This profile becomes part of the maturity library%u2014a database of mix-specific strength curves. For every future pour with the same formulation, the program uses this stored curve in combination with live temperature measurements to forecast strength development. At the same time, test cubes or test cylinders stored in the Match-Cure enclosure continue to validate the predictions by curing under identical conditions to the element itself. When the program signals that the target maturity has been reached, a simple strength test of the match-cured test cubes or cylinders verifies that the concrete has achieved the predicted strength.Managing the Curing Facility with Predictive ControlThe combination of Match-Cure and AutoCure%u00ae turns maturity prediction into a facility-wide control system. Operators can follow strength gain in real-time and receive alerts if curing deviates from expectations, such as delays caused by colder ambient conditions, unexpected thermal gradients or a break-down in the curing system. Production planning becomes more reliable, as teams know exactly when forms can be demoulded or prestressed concrete elements can be released and can schedule production personnel accordingly.Insulated Match-Cure environmental chamber with test specimen with internal concrete temperature measurement. SOMMER Anlagentechnik GmbHBenzstrasse 1 | D-84051 Altheim/GermanyTel: +49 (0) 87 03 / 98 91-0 | Fax: +49 (0) 87 03 / 98 91-25info@sommer-precast.de | www.sommer-precast.de| Stationary line production| Tilting tables| Pallet circulation plants| Transport and handling systems| Multi-Function-Shuttering-Robot (MFSR)| Concrete distribution systems for all purposes| Compacting systems| Finishing equipment| Shuttering systems| Shuttering for special purpose elements| Moulds for garages/moulds for rooms/special purpose elements| Shuttering for skeleton building systems| Moulds for columns/moulds for girders/moulds for TT-elements| Insulation-Process-Application-Robot (IPAR)| Shuttle-Processing-Plant (SPP)Production Engineering and Automation Systems for the Prefabricated Concrete Element Industry