Page 138 - Demo

P. 138

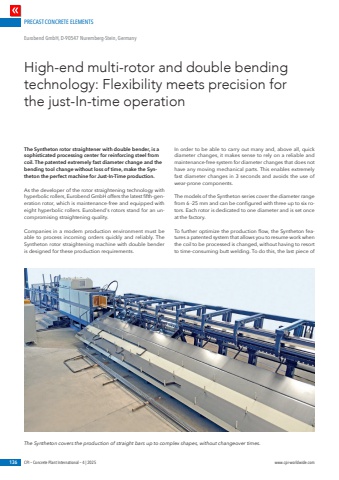

PRECAST CONCRETE ELEMENTS136 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comThe Syntheton rotor straightener with double bender, is a sophisticated processing center for reinforcing steel from coil. The patented extremely fast diameter change and the bending tool change without loss of time, make the Syntheton the perfect machine for Just-In-Time production.As the developer of the rotor straightening technology with hyperbolic rollers, Eurobend GmbH offers the latest fifth-generation rotor, which is maintenance-free and equipped with eight hyperbolic rollers. Eurobend's rotors stand for an uncompromising straightening quality.Companies in a modern production environment must be able to process incoming orders quickly and reliably. The Syntheton rotor straightening machine with double bender is designed for these production requirements.In order to be able to carry out many and, above all, quick diameter changes, it makes sense to rely on a reliable and maintenance-free system for diameter changes that does not have any moving mechanical parts. This enables extremely fast diameter changes in 3 seconds and avoids the use of wear-prone components.The models of the Syntheton series cover the diameter range from 6 -25 mm and can be configured with three up to six rotors. Each rotor is dedicated to one diameter and is set once at the factory.To further optimize the production flow, the Syntheton features a patented system that allows you to resume work when the coil to be processed is changed, without having to resort to time-consuming butt welding. To do this, the last piece of High-end multi-rotor and double bending technology: Flexibility meets precision for the just-In-time operationEurobend GmbH, D-90547 Nuremberg-Stein, GermanyThe Syntheton covers the production of straight bars up to complex shapes, without changeover times.