Page 162 - Demo

P. 162

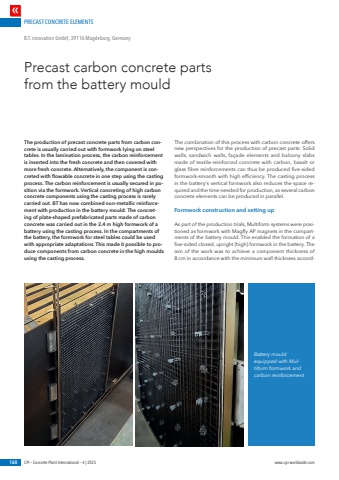

PRECAST CONCRETE ELEMENTS160 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comThe production of precast concrete parts from carbon concrete is usually carried out with formwork lying on steel tables. In the lamination process, the carbon reinforcement is inserted into the fresh concrete and then covered with more fresh concrete. Alternatively, the component is concreted with flowable concrete in one step using the casting process. The carbon reinforcement is usually secured in position via the formwork. Vertical concreting of high carbon concrete components using the casting process is rarely carried out. BT has now combined non-metallic reinforcement with production in the battery mould: The concreting of plate-shaped prefabricated parts made of carbon concrete was carried out in the 2.4 m high formwork of a battery using the casting process. In the compartments of the battery, the formwork for steel tables could be used with appropriate adaptations. This made it possible to produce components from carbon concrete in the high moulds using the casting process.The combination of this process with carbon concrete offers new perspectives for the production of precast parts: Solid walls, sandwich walls, fa%u00e7ade elements and balcony slabs made of textile-reinforced concrete with carbon, basalt or glass fibre reinforcements can thus be produced five-sided formwork-smooth with high efficiency. The casting process in the battery's vertical formwork also reduces the space required and the time needed for production, as several carbon concrete elements can be produced in parallel. Formwork construction and setting upAs part of the production trials, Multiform systems were positioned as formwork with Magfly AP magnets in the compartments of the battery mould. This enabled the formation of a five-sided closed, upright (high) formwork in the battery. The aim of the work was to achieve a component thickness of 8 cm in accordance with the minimum wall thickness accordPrecast carbon concrete parts from the battery mouldB.T. innovation GmbH, 39116 Magdeburg, GermanyBattery mould equipped with Multiform formwork and carbon reinforcement