Page 90 - Demo

P. 90

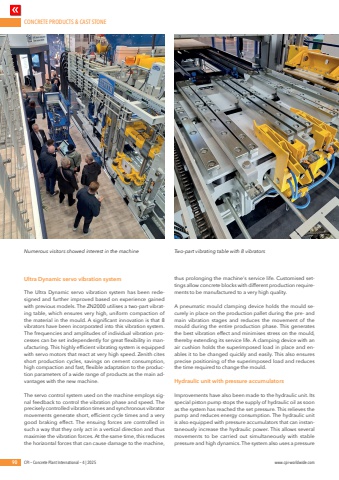

CONCRETE PRODUCTS & CAST STONE90 CPI %u2013 Concrete Plant International %u2013 4 | 2025 www.cpi-worldwide.comUltra Dynamic servo vibration system The Ultra Dynamic servo vibration system has been redesigned and further improved based on experience gained with previous models. The ZN2000 utilises a two-part vibrating table, which ensures very high, uniform compaction of the material in the mould. A significant innovation is that 8 vibrators have been incorporated into this vibration system. The frequencies and amplitudes of individual vibration processes can be set independently for great flexibility in manufacturing. This highly efficient vibrating system is equipped with servo motors that react at very high speed. Zenith cites short production cycles, savings on cement consumption, high compaction and fast, flexible adaptation to the production parameters of a wide range of products as the main advantages with the new machine. The servo control system used on the machine employs signal feedback to control the vibration phase and speed. The precisely controlled vibration times and synchronous vibrator movements generate short, efficient cycle times and a very good braking effect. The ensuing forces are controlled in such a way that they only act in a vertical direction and thus maximise the vibration forces. At the same time, this reduces the horizontal forces that can cause damage to the machine, thus prolonging the machine's service life. Customised settings allow concrete blocks with different production requirements to be manufactured to a very high quality.A pneumatic mould clamping device holds the mould securely in place on the production pallet during the pre- and main vibration stages and reduces the movement of the mould during the entire production phase. This generates the best vibration effect and minimises stress on the mould, thereby extending its service life. A clamping device with an air cushion holds the superimposed load in place and enables it to be changed quickly and easily. This also ensures precise positioning of the superimposed load and reduces the time required to change the mould. Hydraulic unit with pressure accumulators Improvements have also been made to the hydraulic unit. Its special piston pump stops the supply of hydraulic oil as soon as the system has reached the set pressure. This relieves the pump and reduces energy consumption. The hydraulic unit is also equipped with pressure accumulators that can instantaneously increase the hydraulic power. This allows several movements to be carried out simultaneously with stable pressure and high dynamics. The system also uses a pressure Numerous visitors showed interest in the machine Two-part vibrating table with 8 vibrators