Page 152 - Demo

P. 152

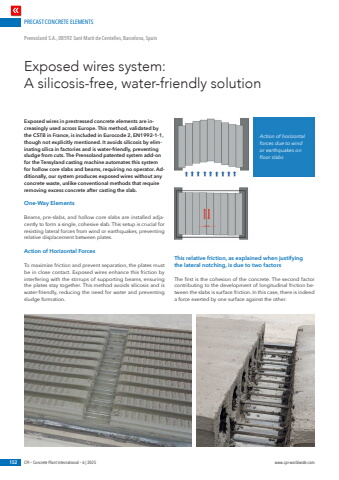

PRECAST CONCRETE ELEMENTS152 CPI %u2013 Concrete Plant International %u2013 6 | 2025 www.cpi-worldwide.comExposed wires in prestressed concrete elements are increasingly used across Europe. This method, validated by the CSTB in France, is included in Eurocode 2, EN1992-1-1, though not explicitly mentioned. It avoids silicosis by eliminating silica in factories and is water-friendly, preventing sludge from cuts. The Prensoland patented system add-on for the Tensyland casting machine automates this system for hollow core slabs and beams, requiring no operator. Additionally, our system produces exposed wires without any concrete waste, unlike conventional methods that require removing excess concrete after casting the slab. One-Way ElementsBeams, pre-slabs, and hollow core slabs are installed adjacently to form a single, cohesive slab. This setup is crucial for resisting lateral forces from wind or earthquakes, preventing relative displacement between plates. Action of Horizontal ForcesTo maximize friction and prevent separation, the plates must be in close contact. Exposed wires enhance this friction by interfering with the stirrups of supporting beams, ensuring the plates stay together. This method avoids silicosis and is water-friendly, reducing the need for water and preventing sludge formation. This relative friction, as explained when justifying the lateral notching, is due to two factorsThe first is the cohesion of the concrete. The second factor contributing to the development of longitudinal friction between the slabs is surface friction. In this case, there is indeed a force exerted by one surface against the other.Exposed wires system: A silicosis-free, water-friendly solutionPrensoland S.A., 08592 Sant Mart%u00ed de Centelles, Barcelona, SpainAction of horizontal forces due to wind or earthquakes on floor slabs